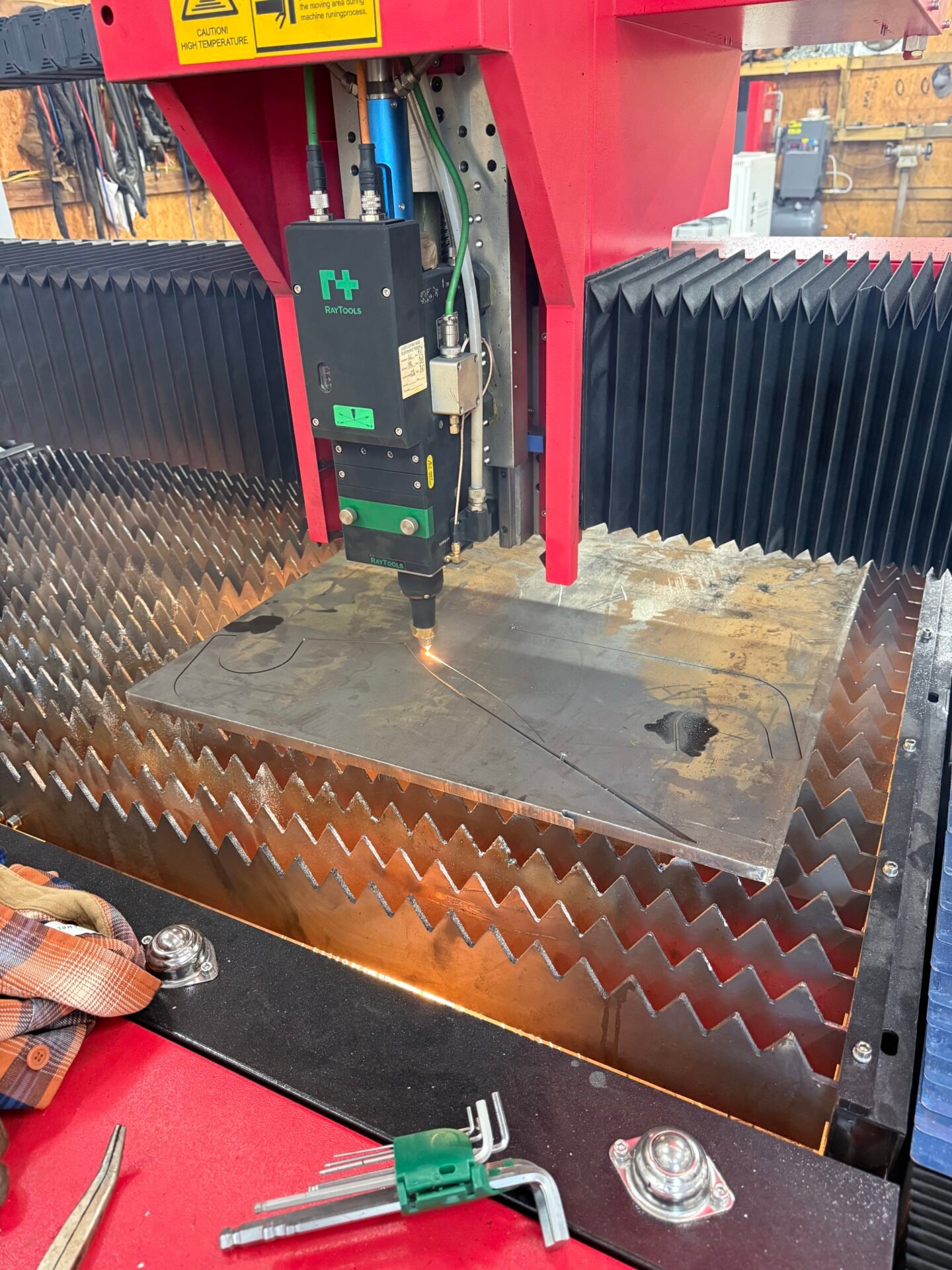

At Whitefield Welding, we specialize in high-precision CNC fiber laser cutting to deliver clean, accurate, and efficient results for all your metalworking projects. Our state-of-the-art CNC fiber laser cutting machines are designed to handle a variety of materials, including steel, aluminum, and stainless steel, making them perfect for both simple and intricate designs.

Whether you’re working on large-scale production runs or custom one-off pieces, our CNC fiber laser cutting services ensure minimal material waste, fast turnaround times, and consistent high-quality cuts. We work with businesses across multiple industries, providing reliable and cost-effective solutions tailored to meet your specific needs.

CNC fiber laser cutting can handle a wide range of materials, including steel, aluminum, stainless steel, and other conductive metals. It’s ideal for cutting various thicknesses depending on the material.

CNC fiber laser cutting offers high precision, faster cutting speeds, and minimal material waste compared to traditional methods like plasma cutting or mechanical cutting. It’s also more cost-effective for large production runs.

CNC fiber laser cutting is highly accurate, with minimal tolerance levels. It can produce cuts with precision for both simple and complex shapes, ensuring consistency across projects.

Yes, CNC fiber laser cutting is perfect for custom designs. Whether you need intricate patterns or specific shapes, the CNC fiber laser cutting system can create custom pieces tailored to your specifications.

CNC fiber laser cutting is a very fast and efficient process. Depending on the material and thickness, it can quickly produce high-quality cuts, making it an excellent choice for both small-scale and large-scale production projects.